Scientific Incubator Shaker Systems for Precision Laboratory Research

Integrating two critical laboratory functions into a single unit, an incubator shaker provides a controlled environment for the simultaneous incubation and agitation of biological samples. Unlike a standard lab incubator, which maintains static conditions, or a standalone shaker, which operates at ambient room temperature, this hybrid apparatus ensures that culture growth occurs under optimized thermal and kinetic parameters. These systems are foundational in a scientific laboratory, supporting workflows that range from bacterial aeration to sensitive mammalian cell expansion.read more

An incubator shaker is engineered to maintain rigorous uniformity across parameters such as temperature, agitation speed, and, in advanced models, atmospheric composition (such as CO2). Available configurations include a compact benchtop model for space-constrained facilities and a large stackable floor unit designed for high-throughput applications. Selecting the appropriate product ensures experimental reproducibility and efficiency, irrespective of whether the protocol requires a refrigeration function for protein expression at sub-ambient temperatures or high-heat capabilities for thermophilic bacteria.

What Defines a High-Performance Incubator Shaker?

When evaluating a shaking incubator, distinctions in drive mechanics, thermal insulation, and control logic determine the system’s suitability for specific research needs. A robust incubator shaker minimizes vibration while maintaining precise orbital motion, ensuring that every flask on the platform experiences identical conditions.

- Drive Mechanism and Stability: The core of any shaker is its drive system. High-quality units often feature triple-eccentric counterbalanced drives that support heavy loads at high speeds without vibration. This stability is crucial when you shake sensitive samples or operate a fully loaded stackable unit.

- Temperature Uniformity: A superior incubator minimizes thermal gradients. Forced-air circulation systems ensure that the set temperature is consistent throughout the chamber, preventing hot spots that could skew growth rates. For applications requiring cooling, a powerful refrigerator compressor is essential to maintain stability below ambient conditions.

- Capacity and Flexibility: A lab often requires versatility. A benchtop unit might be sufficient for small-scale pilot studies, while a stackable design allows researchers to scale up capacity vertically without consuming additional floor space. Universal platforms with adjustable clamps accommodate various vessel sizes, from microplates to 6-L flasks.

- Control Interface: Modern scientific incubator shaker systems utilize PID controllers for precise regulation of speed and heat. Features such as programmable ramp/soak cycles allow users to automate complex protocols, where the system might incubate at one temperature and then shift to another to induce specific biological activities.

Where is a Scientific Incubator Shaker Essential?

The utility of a shaking incubator spans the entire spectrum of the life sciences. From academic research to biopharmaceutical production, these devices are critical wherever liquid cultures require aeration and thermal regulation.

- Microbiology and Fermentation: Bacterial and yeast cultures rely on vigorous agitation to maintain dissolved oxygen levels. An incubator shaker provides the necessary orbital motion to maximize gas transfer, ensuring high-density biomass production.

- Protein Expression: Many recombinant protein protocols require a specific induction phase. A shaker with active cooling is often used to lower the temperature during the induction step, which helps in proper protein folding and solubility.

- Molecular Biology: Procedures such as DNA plasmid preparation and hybridization often use a compact incubator shaker to ensure thorough mixing of reagents at elevated temperatures.

- Cell Culture: While often associated with static incubators, suspension-adapted mammalian and insect cells require gentle agitation. A specialized CO2 incubator shaker provides the necessary pH control and low-shear environment for these delicate applications.

Showing 1–12 of 14 results

Category

- Bioreactors+

- Parallel Bioreactors

- Single-Use Bioreactors

- Stirred-Tank Bioreactors

- Capillary Electrophoresis Instruments+

- Capillary Gel Electrophoresis (CGE)

- Capillary Isoelectric Focusing (CIEF)

- Capillary Zone Electrophoresis (CZE)

- Cell Counters and Analyzers+

- Automated Cell Counters

- Manual Cell Counters

- Cellular Imaging Systems+

- Fluorescence Imaging Systems

- High-Content Imaging Systems

- Live-Cell Imaging Systems

- Centrifuges+

- Benchtop Centrifuges

- Clinical Centrifuges

- Micro Centrifuges

- Refrigerated Centrifuges

- Ultracentrifuges

- Chromatography Instruments+

- Gas Chromatography

- Ion Chromatography

- Liquid Chromatography

- Flow Cytometer+

- Cell Analyzers

- Cell Isolation Systems

- Cell Sorters

- High-Throughput Flow Cytometers

- Imaging Flow Cytometry

- Personal Flow Cytometers

- Portable/Benchtop Flow Cytometers

- Spectral Flow Cytometers

- Laboratory Incubators+

- CO2 Incubators

- Dry Bath Incubators

- Hypoxia Incubators and Chambers

- Incubator Shakers

- Laboratory Ovens

- Portable Incubators

- Thermal Mixers

- Laboratory Microscopes+

- Atomic Force Microscopes (AFM)

- Automated Modular Microscopes

- Compound Microscopes

- Confocal Microscopes

- Digital Microscopes

- Fluorescence Microscopes

- Inverted Microscopes

- Live Cell Imaging Microscopes

- Metallurgical Microscopes

- Multiphoton Microscopes

- Polarizing Microscopes

- Raman Microscopes

- Scanning Electron Microscopes (SEM)

- Stereo Microscopes

- Super-Resolution Microscopes

- Transmission Electron Microscopes (TEM)

- Upright Microscopes (Neuroscience)

- Liquid Handlers+

- Automated Pipetting Systems

- Multi-Channel Liquid Handlers

- Robotic Liquid Handlers

- Variable Volume Pipetting Systems

- Mass Spectrometers+

- Ambient Ionization

- APCI MS

- ESI MS

- FT ICR MS

- ICP MS

- Orbi Trap MS

- Quadrupole MS

- Time-of-Flight MS

- Microarray Scanners+

- DNA Microarray Scanners

- Laser-Based Microarray Scanners

- Microplate Readers+

- Absorbance Microplate Readers

- Fluorescence Microplate Readers

- Luminescence Microplate Readers

- Multimode Microplate Readers

- Particle Counters and Analyzers+

- Airborne Particle Counters

- Laser Diffraction Analyzers

- Liquid Particle Counters

- Nanoparticle Analyzers

- Portable Particle Counters

- Remote Particle Counters

Brand

- ACCU-SCOPE

- Agilent

- Airmodus

- Alphasense

- Analytik Jena

- ARGO-HYTOS

- Arrayit

- Aurora Biomed Inc.

- Azure Biosystems

- Baker

- BD Biosciences

- Beckman Coulter

- Beijing Challen Biotechnology

- Binder

- Bio-Techne

- Biobase

- BioRad

- BMG Labtech

- Bruker

- Celestron

- Cellbox

- Centurion Scientific Ltd

- ChemoMetec

- CleanAir

- Cleatech

- Corning

- Countstar

- CS Instruments

- CUBIC

- Cytek Biosciences

- Cytena

- Cytiva

- Data Technologies

- Descase

- Electrolab Biotech

- Eppendorf

- Euromex

- Evident

- Fermex

- Fluke

- Formulatrix

- Getinge

- Gilson

- GPC Bio

- Haier Biomedical

- Hamilton Company

- Hettich

- Hitachi High-Tech

- Hudson Robotics Inc.

- Hydro

- INFORS HT

- Innopsys

- Jasco

- Jeiotech

- JEOL

- Kanomax

- Keyence

- KNAUER

- LAB-KITS

- Labomed

- Labwit

- Leco

- Leica

- Lighthouse

- Logos Biosystems

- LOSI

- Lumex Instruments

- Luminex

- Malvern Panalytical

- Meiji Techno

- Memmert

- Merck

- Mettler-Toledo International Inc.

- Miltenyi Biotec

- Molecular Devices

- Motic

- MP Filtri

- MSE (Medical and Scientific Equipment)

- NCI

- Nikon Instruments

- NuAire

- ORFLO Technologies

- Oxford Instruments

- PAMAS

- Particle Measuring Systems

- Particles Plus

- PBS Biotech

- PCE instruments

- PerkinElmer

- PharSol

- PHCbi

- Prior Scientific

- Promega

- Qiagen NV

- Revvity

- RION

- Sartorius

- SATAKE

- Sciex

- Sebia

- SETA

- Setra

- Shimadzu

- SIBATA

- Sigma Laborzentrifugen GmbH

- Solaris Biotech

- Solida Biotech

- Sony Biotechnology Inc.

- SPT Labtech Ltd

- Stratedigm Inc.

- Sysmex Corporation

- Tecan

- TES

- Thermo Fisher Scientific

- TSI

- Waters

- Western States Machine Company

- ZEISS

- ZETRON

-

Agilent BioTek BioSpa 8

Automated incubator for 8-plate workflows with integrated environmental control.

-

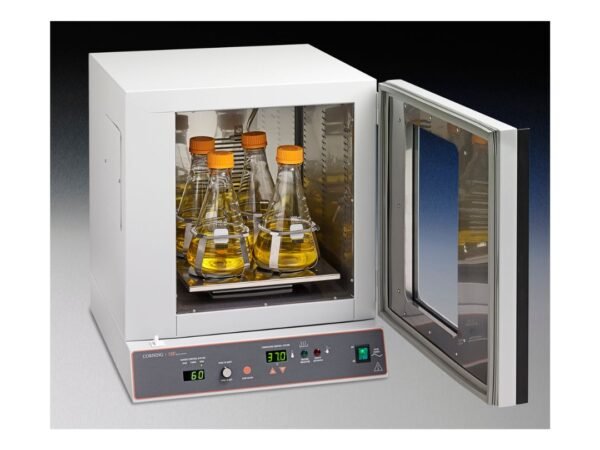

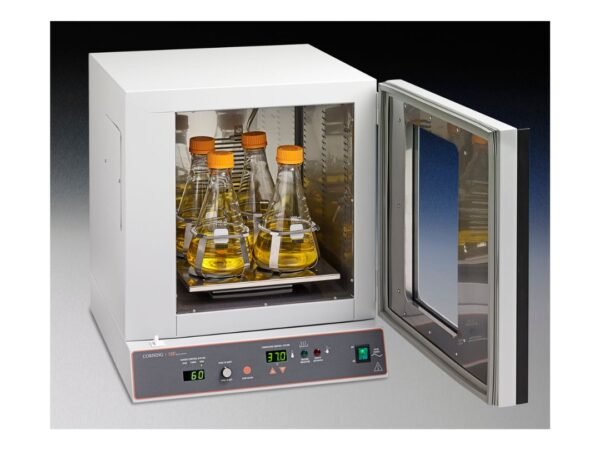

Corning® LSE™ Benchtop Shaking Incubator with Platform, 120V, US Plug product no 6790

The Corning LSE Benchtop Shaking Incubator 6790 delivers precise temperature control & orbital shaking. Complete with a versatile platform, it is ...

-

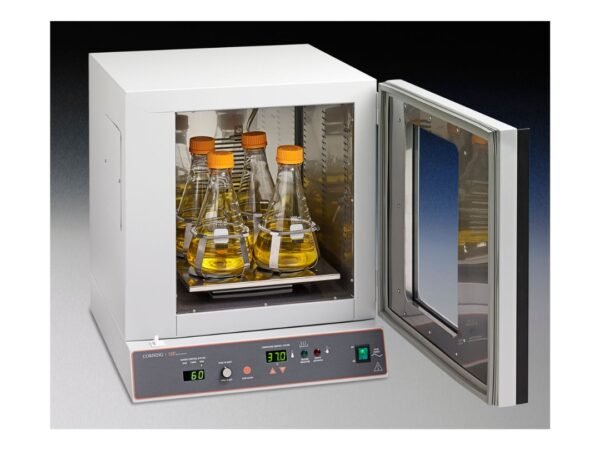

Corning® LSE™ Benchtop Shaking Incubator with Platform, 230V, Chinese Plug product no 6792

Corning LSE Benchtop Shaking Incubator (6792) offers precise temperature control and orbital shaking. This 230V unit with a Chinese plug ensures consi...

-

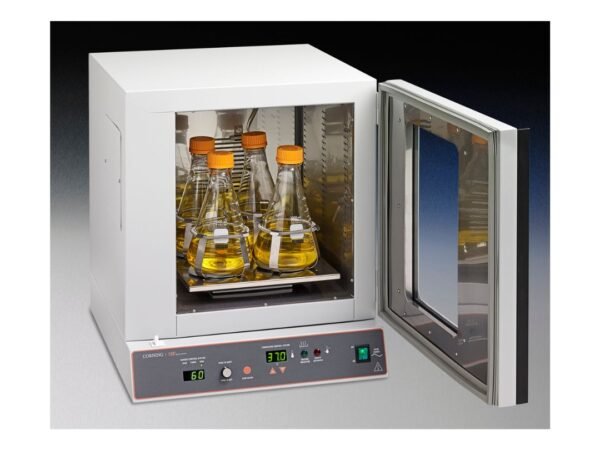

Corning® LSE™ Benchtop Shaking Incubator with Platform, 230V, EU Plug product no 6791

The Corning LSE Benchtop Shaking Incubator with Platform provides precise temperature control and consistent orbital shaking. Ideal for sensitive biol...

-

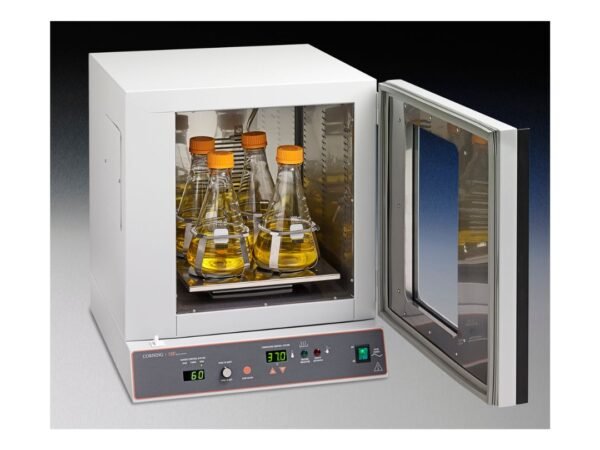

Corning® LSE™ Shaking Incubator, 49 Liters, 120V, US Plug product no 6750

The Corning LSE Shaking Incubator provides precise temperature control and consistent orbital shaking. With a 49-liter capacity, it's ideal for cell c...

-

Corning® LSE™ Shaking Incubator, 49 Liters, 230V, Chinese Plug product no 6761

Corning LSE Shaking Incubator (6761) provides precise temperature control & orbital shaking for biological samples. With 49L capacity, 230V, &...

-

Corning® LSE™ Shaking Incubator, 49 Liters, 230V, EU and UK Plug product no 6752

The Corning LSE Shaking Incubator (6752) provides precise temperature control & orbital shaking within a 49-liter chamber. This 230V unit is perfe...

-

Corning® LSE™ Shaking Incubator, 71 Liters, 120V, US Plug product no 6753

The Corning LSE Shaking Incubator 6753 provides efficient temperature control & orbital shaking. Its 71-liter capacity supports diverse lab applic...

-

Corning® LSE™ Shaking Incubator, 71 Liters, 230V, Chinese Plug product no 6762

The Corning LSE 71 Liter Shaking Incubator provides reliable mixing & stable temperature control for life science labs. Essential for sensitive bi...

-

Corning® LSE™ Shaking Incubator, 71 Liters, 230V, EU and UK Plug product no 6754

The Corning LSE Shaking Incubator, 71 Liters, 230V, EU & UK plug, offers precise temperature control & orbital shaking. Perfect for cell cultu...

-

Thermo Fisher Scientific Cytomat™ 2 Selector Automated Shaking Incubator catalog no 51035241

The Thermo Scientific Cytomat 2 Selector Automated Shaking Incubator simplifies biotherapeutics workflows. Features large amplitude shaking to overcom...

-

Thermo Fisher Scientific Cytomat™ 2 Selector Automated Shaking Incubator catalog no 51035242

The Cytomat 2 Selector Automated Shaking Incubator simplifies biotherapeutics workflows. Featuring large amplitude shaking, it overcomes cell growth l...